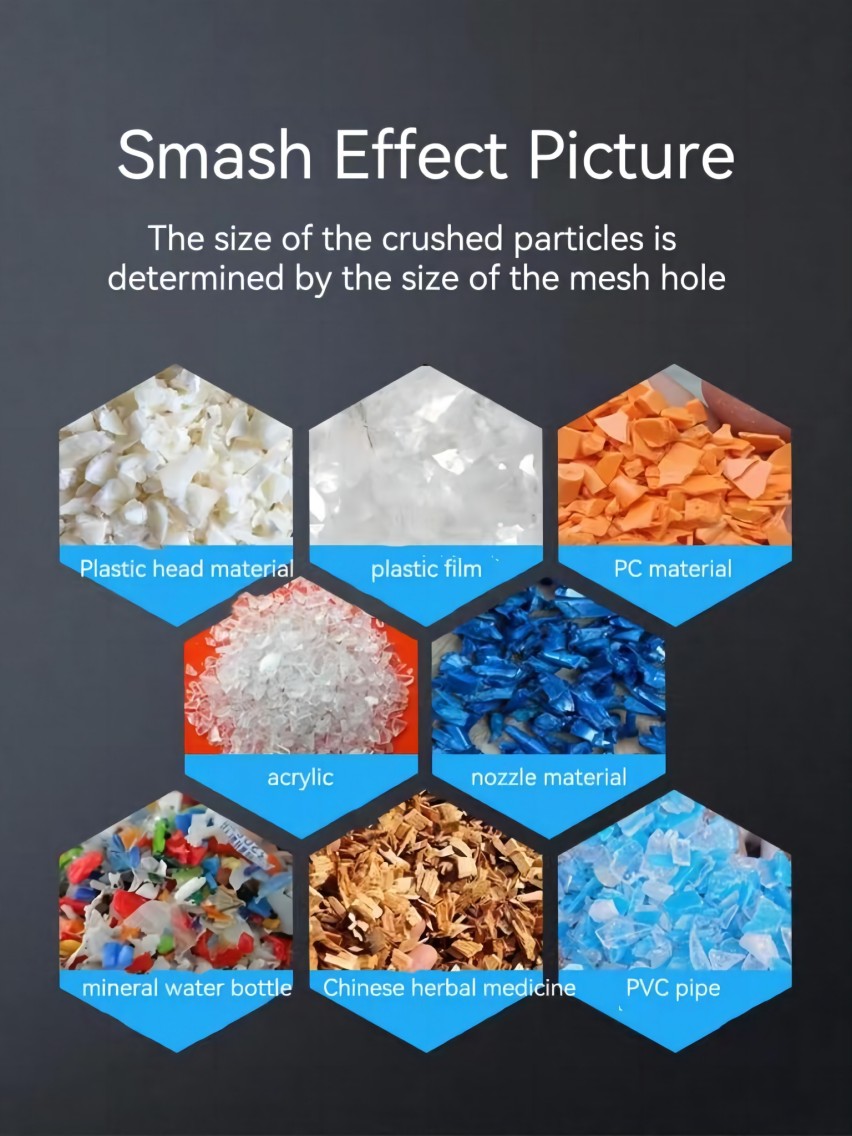

Plastic mill refers to the crushing of various plastic plastics and rubber such as plastic profiles, tubes, rods, threads, films, and waste rubber products. The pellets can be directly extruded and used as raw materials for production.

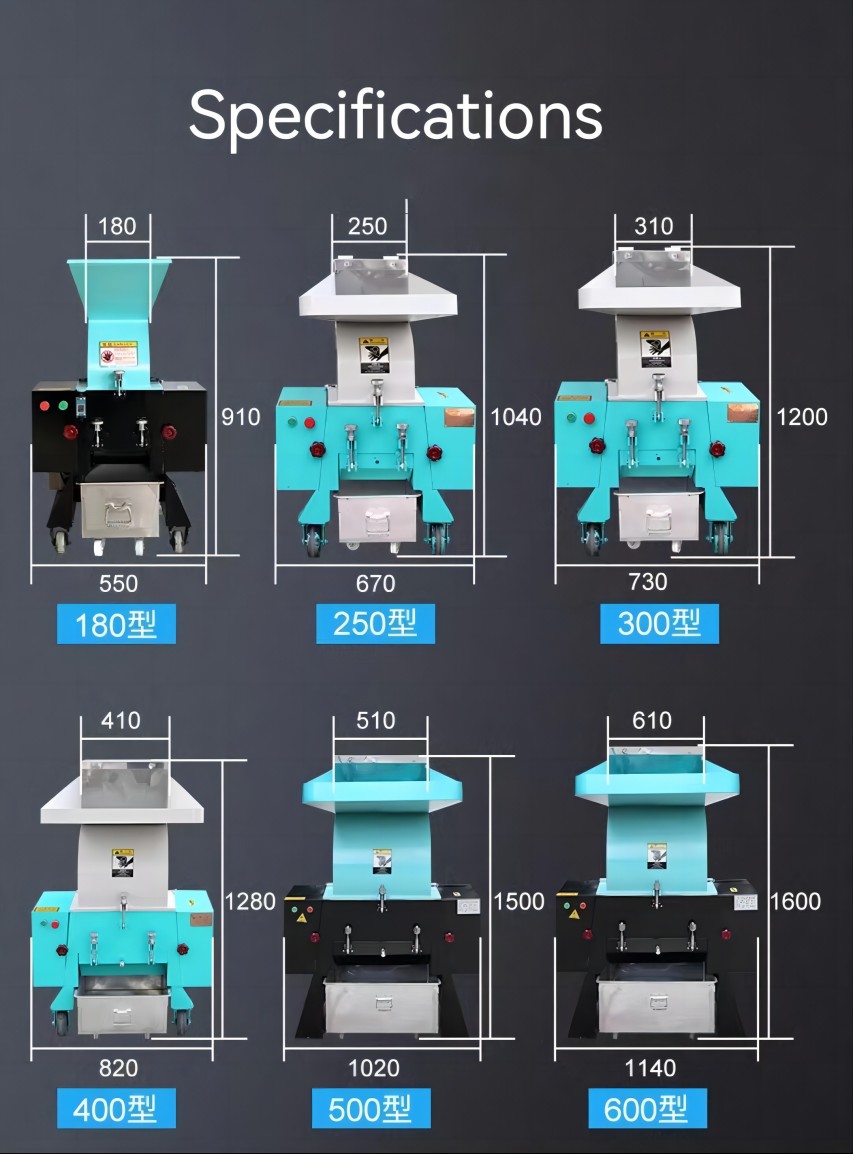

This type of machine uses alloy steel blades with long service life; at the same time, the machine adopts a separate design, which is easy to repair and clean. It has a double-layer structure and is equipped with sound insulation materials, so the noise is very low. The cutter spindle seat has undergone strict balance tests, and the machine The base is equipped with four wheels for easy movement.

Time saving: Recycle immediately within 30 seconds, no need to wait for centralized crushing, and ensure cleanliness;

Improve quality: After the nozzle material is taken out at high temperature, it will be oxidized, humidified (absorbed water) and destroy the physical properties. Recycling it immediately within 30 seconds can reduce the physical strength and reduce the damage to the color and gloss.

Save money: Short-term recycling avoids contamination and the defective rate caused by mixing, which can reduce the waste and loss of plastic, labor, management, warehousing, and material purchase funds;

Wide range of uses: suitable for crushing and recycling PU, PVC, PC, ABC and other soft and hard materials;

Simple: Easy-to-disassemble design, easy to change color and material, compact and takes up less space, suitable for use next to the machine in a small workshop;

It uses a medium-speed motor with low noise and low energy consumption; the motor is equipped with an overload protection device and a power interlock protection system, making operation and cleaning safe and reliable;

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China