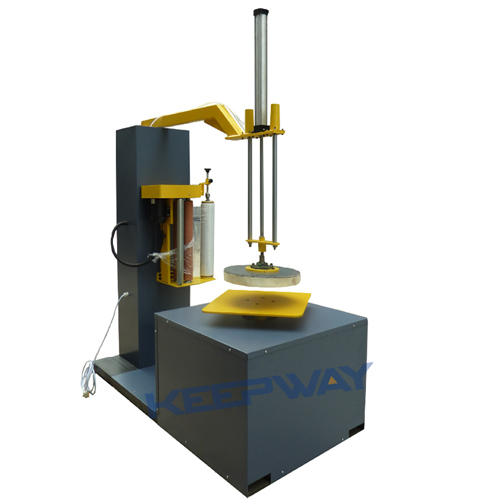

Mini Stretch Wrapping Machine / Packing Machine

Introduction of Mini Stretch Wrapping Machine:

The min stretch wrapping machine /mini stretch packing machine /mini stretch wrapper uses PE wrapping film to wrap the bulk pallet goods. This equipment can improve logistics efficiency, reduce loss during transportation, and has the advantages of dust-proof, moisture-proof, and reduced packaging costs. This model is suitable for small and light goods.It is widely used in glass products, hardware tools, electronic appliances, paper-making, ceramics, chemicals, food, beverages, building materials and other industries.

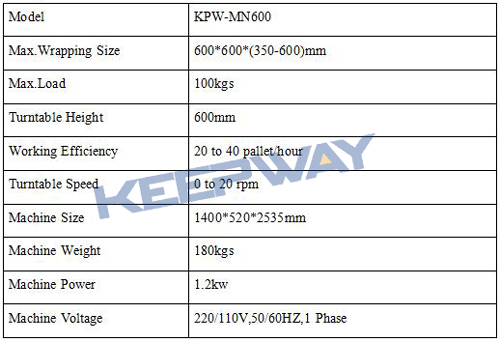

Technology Parameter of Mini Stretch Wrapping Machine:

Features of Mini Stretch Wrapping Machine:

Control System:

1) With a separate PLC programming control system, the number of winding layers and times can be set;

2) The screen displays the PLC operation display interface;

3) Photoelectric switch, which automatically senses the height of the goods;

4) The top layer, bottom layer, and the number of reciprocating laps can be set individually;

5) The photoelectric switch is turned on and off; the film breaking and film shortage alarm can be set in the operation screen.

6) The machine has the function of detecting faults. If there is a fault, open the "monitoring interface" to monitor the machine failure

7) The device has a one-key restore to factory settings function. When the user adjusts the parameters of the device in confusion, he can press the one-key restore button to restore the factory settings and reset the parameters.

Turntable Drive:

1) Turntable frequency conversion speed regulation 0~12 rpm adjustable;

2) The drive of the turntable is a chain drive, and the positioning is accurate;

3) The turntable is automatically reset, which is convenient for loading and unloading goods on the spot.

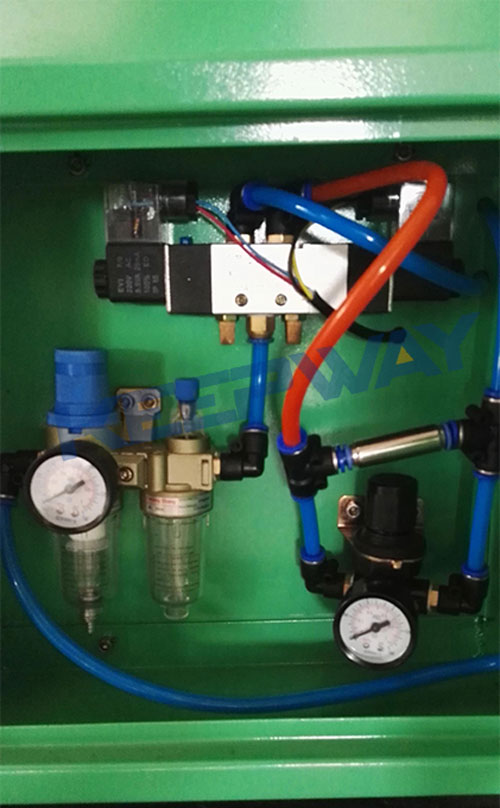

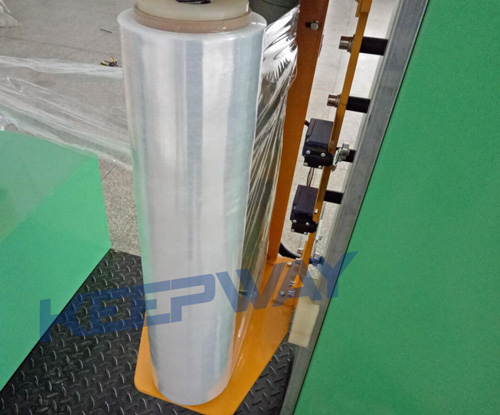

Film Carriage System:

1) The film carriage is an AC motor pre-stretching mechanism, equipped with frequency conversion speed regulation;

2) Adjusting the film tension, the pre-stretching can reach 250%;

3) 10A double chain structure, stable and reliable;

4) The raising and lowering speeds of the film carriage and the film feeding speed are adjustable by frequency conversion;

5) The wrapping numbers of the top and bottom are separately controlled;

6) Membrane system follow-up mechanism, just pull it;

7) Install a photoelectric switch on the film carriage to automatically detect the height of the goods.

Column Structure:

1) Double chain structure, stable and reliable

2) The lifting chain adopts 10A chain transmission, which has high service life and wear resistance

3) The column has a convenient maintenance module

4) The column box: wall thickness 1.5mm, upper and lower plates 6mm, inner corner reinforcement plate 6mm

Surface Treatment:

The whole machine adopts outdoor plastic powder spraying treatment, which is resistant to abrasion and rust

PLC Programmable Control

Photoelectric Switch, Automatically Sensing The Height Of The Goods

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China