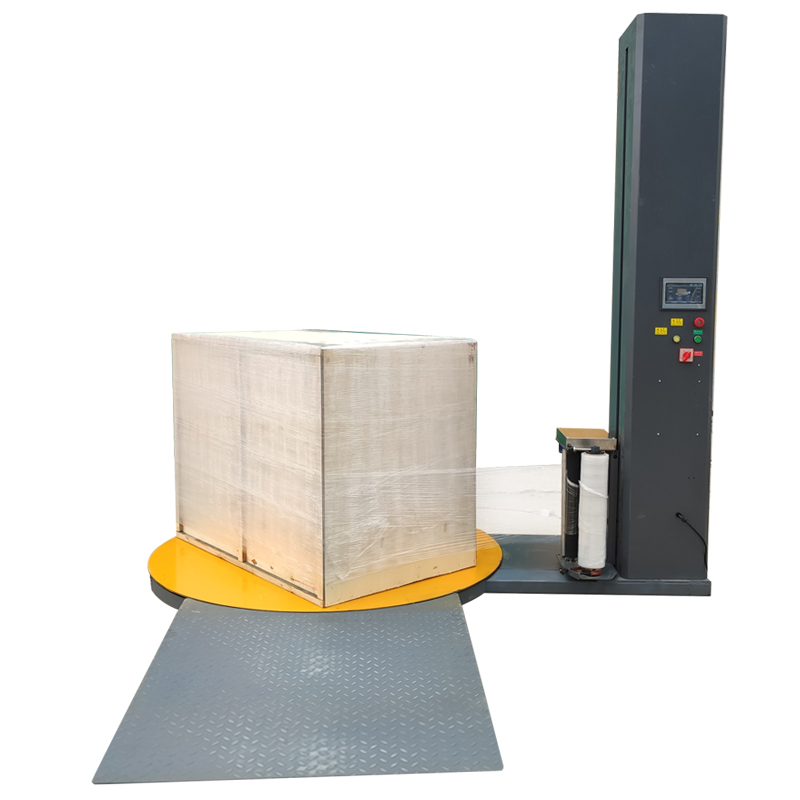

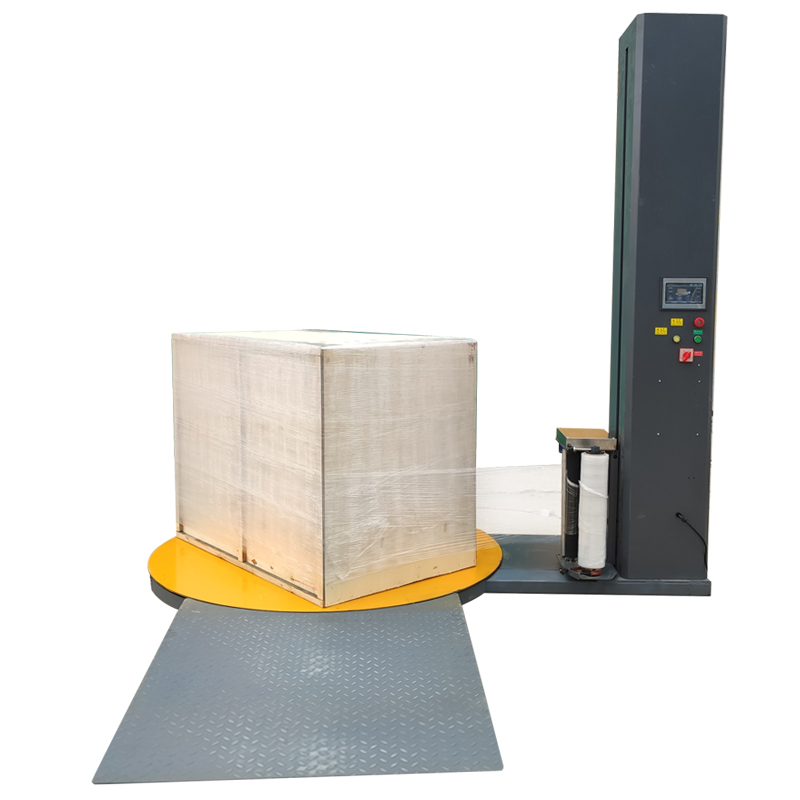

How to solve the packaging of heavy cargo pallets——Pallet wrapping machine can help you

The equipment is used to wrap the goods by rotating the turntable to drive the pallet goods to rotate.

Application

1 Applied to the wrapping packaging of single goods or multiple small goods.

The top pressing device ensures that the goods are stable during the packaging process, and the packaging height can be customized according to customer requirements! At the same time, according to the actual needs of packaging, two types of equipment can be selected: film frame fixed and film frame moving up and down. Widely used in glass products, hardware tools, electronic appliances, papermaking, ceramics, chemicals, food, beverages, building materials and other industries. It can improve packaging efficiency, reduce losses during transportation, and has the advantages of dustproof, moisture-proof, and reducing packaging costs. It is an ideal choice for intensive packaging. Basic features: double-ring transmission, reciprocating work. Safe and convenient. Frequency conversion control, the overlap of the packaging belt can be adjusted as needed. The slip ring can move up and down to adapt to steel wires with different inner and outer diameters. The tightness of the packaging belt is adjustable. The rollers and guard rollers are both coated with polyurethane. Equipped with an end tape fixing device. The wrapping machine is mainly used in chemical, electronic, refractory, glass products, papermaking, hardware, food and beverage industries.

2 It is suitable for container transportation of bulk goods and packaging of loose pallets.

. The turntable starts and stops slowly to prevent the goods from falling instantly. The rotating film rack makes the packaging more tightly fitted. Local reinforcement at the required position makes the packaging more perfect. The interval of the film is adjustable, and the packaging material is more economical. The turntable resets to ensure accurate positioning during transportation. Photoelectric height measurement can automatically sense the height of the package, and the number of wrapping layers and packaging times at the bottom and top are easy to adjust. Overload protection is safe and reliable, maintenance is simple, and easy to operate. It is the first choice for manual and electric transport vehicles.

Product Features

1. The production structure of the wrapping machine is stable.

2. Digital electronic control circuit, high stability, long life, and low failure rate.

3. Slow start and stop device to prevent the upper packaging from falling.

4. Touch screen, easy to operate.

5. The upper and lower packaging can be set by inputting data

Main technical parameters

Power/voltage: 1P, AC220V/3P, 380V, 50Hz, 1.25KW

Arm speed: 0~14r/min (adjustable)

Standing column height: 2000mm

Pallet size: Packaging diagonal: maximum 2000mm

Height: 2000mm (customizable)

Packaging material specifications: width ≤500mm outer diameter ≤280mm

LLDPE Wrapping Film machine size: L (4000) x W (2000) x H (3120) mm

Machine weight: 1400Kg (gross weight) / 1200Kg (net weight)

Working description:

Film rack system: pre-stretched film rack, pre-stretching up to 250%, automatic film feeding, DC speed control system controls film tension

·Lifting column: double chain structure, lifting speed variable frequency adjustable

·Turntable characteristics: M-shaped opening, can directly enter the hand forklift to load and unload goods;

·Control system: PLC programmable control, button-type operation panel, simple and clear;

·Operation function: automatic operation, automatic completion of machine setting function

Main technical features of Pallet Wrapping Machine:

● Electric drive system: requires less working space than most machines

● Fixed mast: maximum pallet wrapping height, 2000mm

● Microprocessor logic board; 6 different pre-set programmable memories

● There is a mechanical worker brake

● Maintenance-free and sealed battery-no need to power on, directly converted from 220V standard power supply

● Convenient transportation-no need to assemble each component, direct use

Contact information:

Tel:+86-18206519878

Email:sales@kbwmachinery.com

WhatsApp & WeChat:+86 18206519878 available at any time

Website:www.kbwmachinery.com