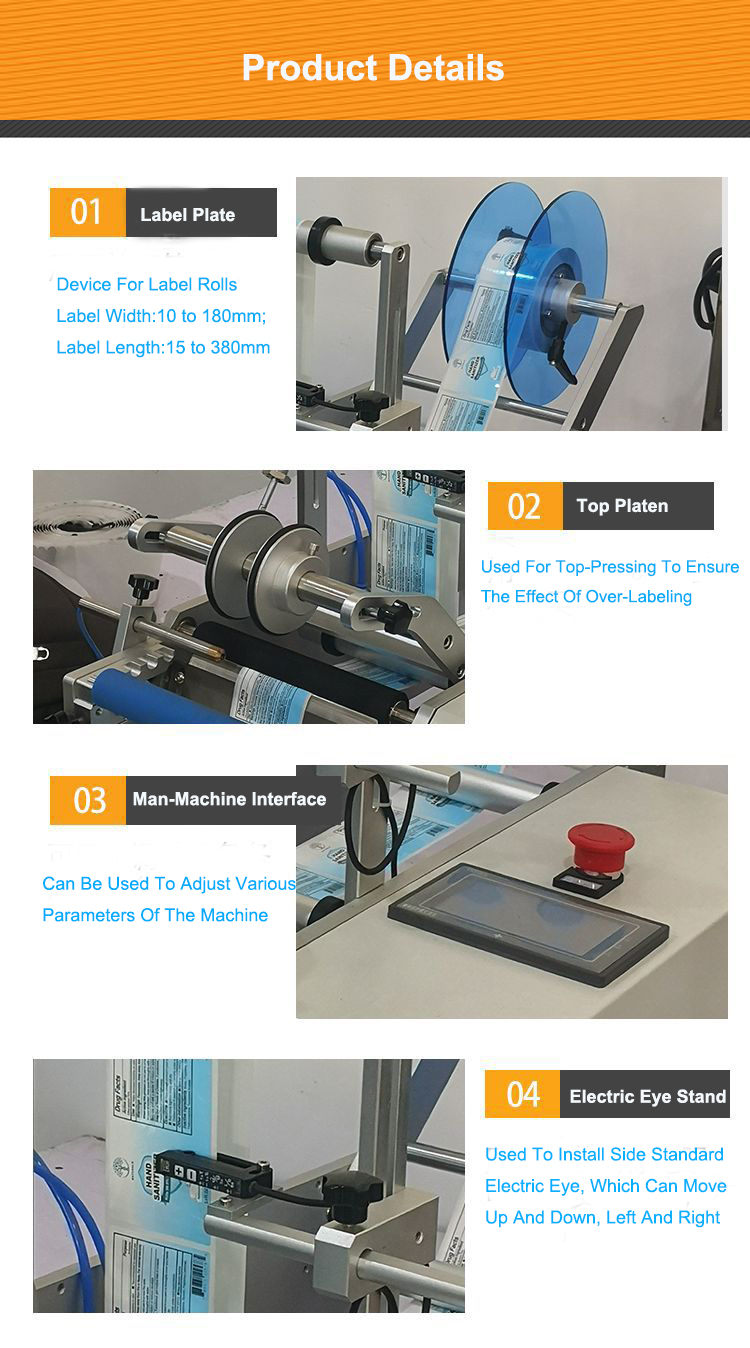

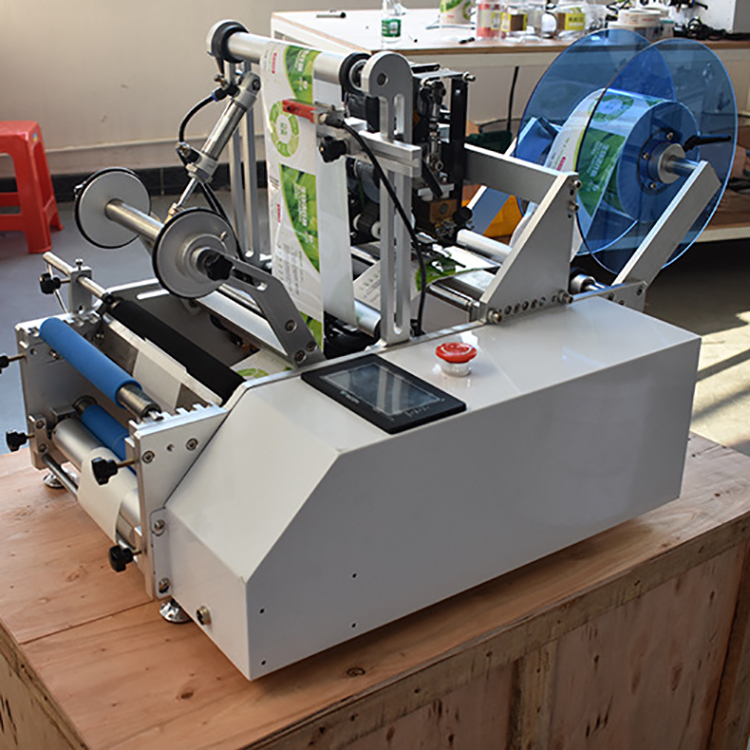

Semi Automatic Round Bottle Labeling Machine/Sticker Label Machine

Introduction of Semi Automatic Round Bottle Labeling Machine:

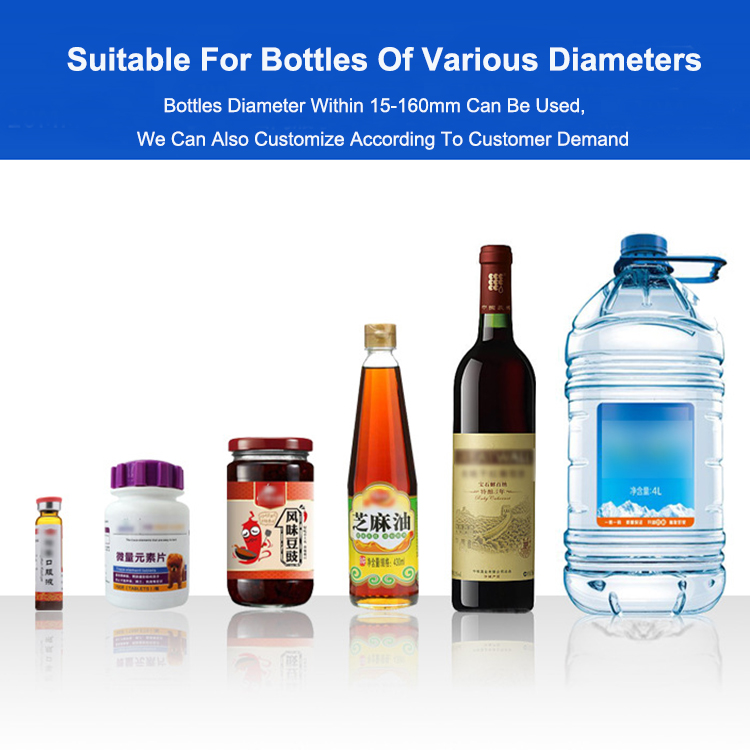

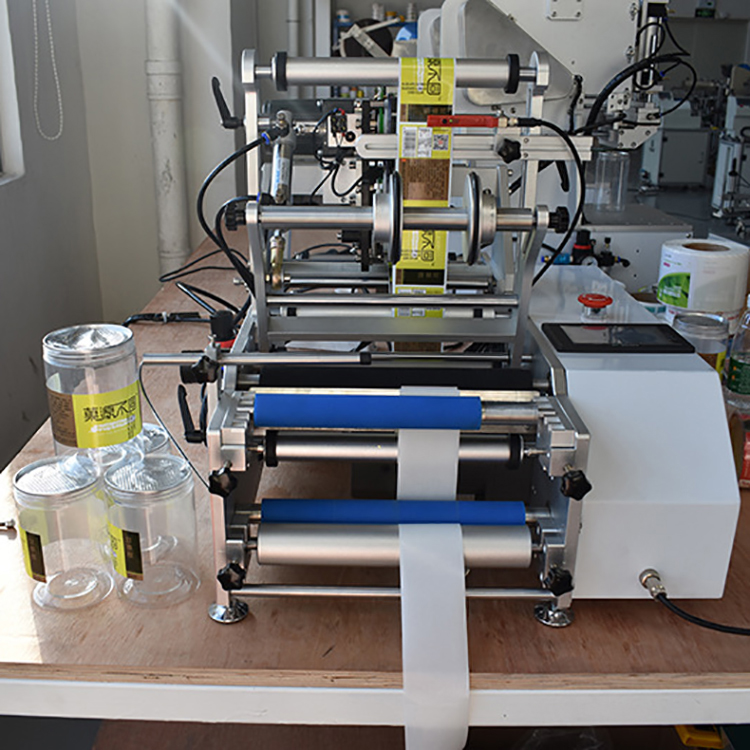

It is suitable for labeling cylindrical objects of various specifications, small taper round bottles, such as xylitol, cosmetic round bottles, wine bottles, etc. It can realize full circle/half circle labeling, circle front and back labeling, and the spacing between front and back labels can be adjusted arbitrarily. It is widely used in food, cosmetics, chemical, pharmaceutical and other industries.

Optional circumferential positioning detection device to realize circumferential positioning and labeling.

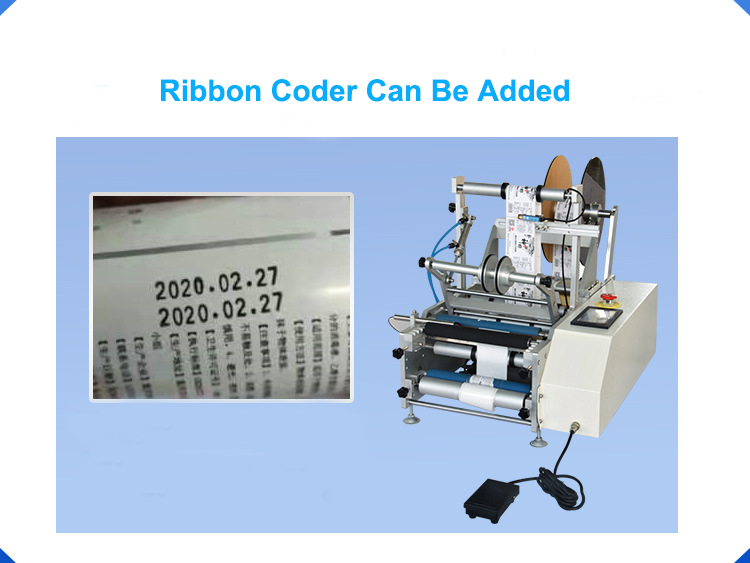

Optional ribbon printer and inkjet printer, labeling and printing production batch number and other information at the same time, reduce packaging procedures and improve production efficiency.

Application range

Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: products that require labels to be affixed to the circumferential and conical surfaces; single label or double label labeling can be applied.

Application industry: widely used in food, medicine, daily chemical, electronics, hardware, plastic and other industries.

Application examples: Oral liquid round bottle labeling, vial labeling, xylitol labeling, shampoo bottle labeling, wine double labeling, wine fixed-point labeling, etc.

Labeling Effect:

Technology parameter of Semi Automatic Round Bottle Labeling Machine:

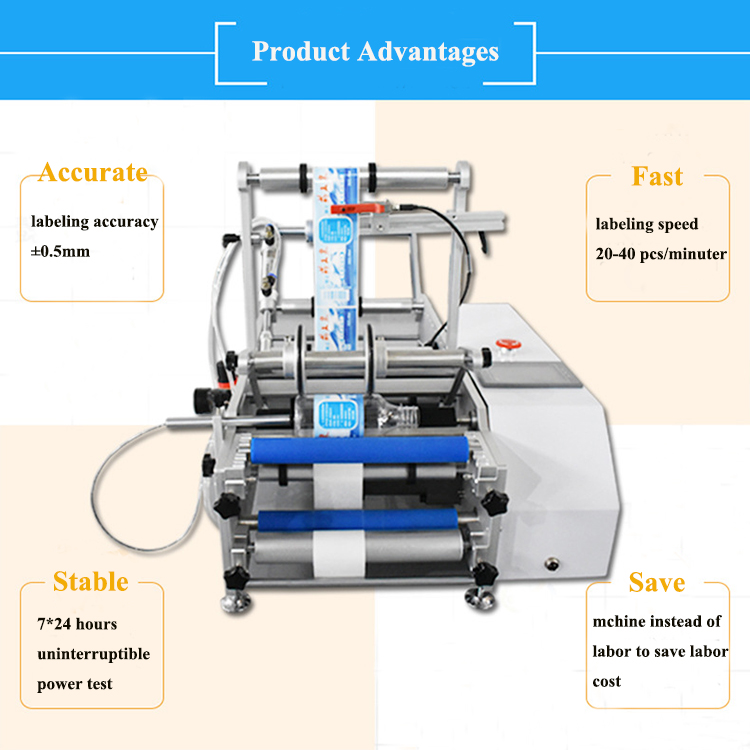

Features of Semi Automatic Round Bottle Labeling Machine:

1. The labeling function can be switched and positioned arbitrarily, and the spacing can be flexibly adjusted;

2. High-quality labeling effect, with dual positioning of product positioning and label correction, high overlap of the label head and tail, no wrinkles, no bubbles;

3. Simple adjustment, one-key switching of various functions, simple and fast switching of different labels, improving efficiency;

4. Safe and clean, in line with GMP production requirements, the main material is stainless steel and high-grade aluminum alloy, which is strong and durable;

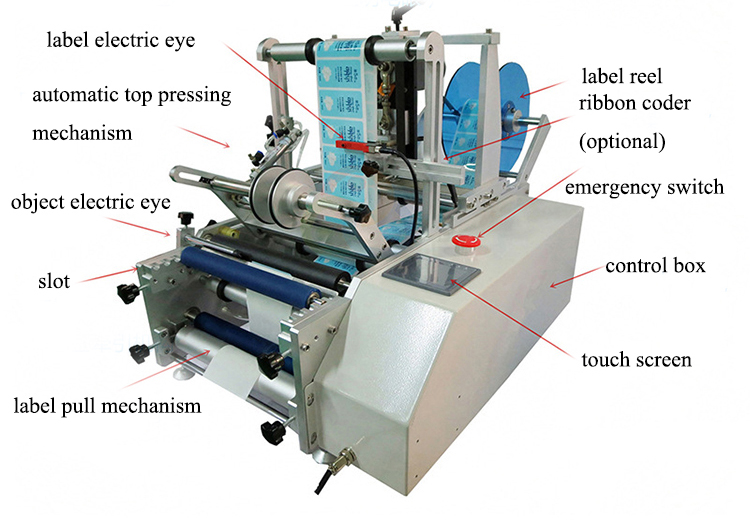

5. Stable performance, using PLC + optical fiber sensor electronic control system control, supporting long-term operation of the equipment;

6. Convenient and efficient production management, with label counting, power saving mode, photoelectric tracking label function;

7. Color touch screen control, with powerful data memory function, all bottle types only need to be adjusted once, only need to call up data when switching bottle types, no need to make adjustments to start operation and production, simple and efficient;

8. Optional functions: hot coding/printing function, circumferential positioning function, automatic induction (customized according to customer requirements).

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China