Automatic Round Bottle Labeling Machine/Sticker Label Machine

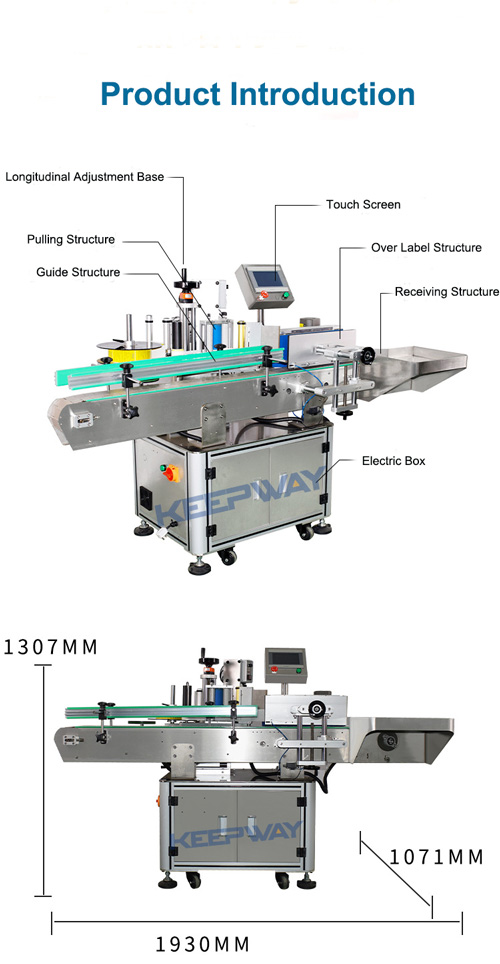

Introduction of Automatic Round Bottle Labeling Machine:

Technology parameter of Automatic Round Bottle Labeling Machine:

Features of Automatic Round Bottle Labeling Machine:

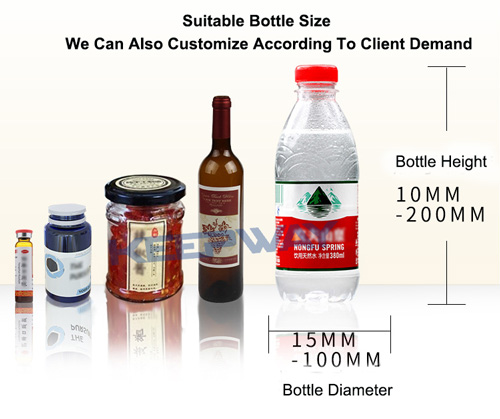

1.Wide range of application, can meet the full-circle labeling or half-circle labeling of round bottles, simple label switching between bottles, easy adjustment;

2.The label overlap is high. The tape is deflected by a correction mechanism. The label does not deviate. The labeling position can be adjusted in eight directions of x / y / z directions and inclination. There are eight degrees of freedom to adjust. ;

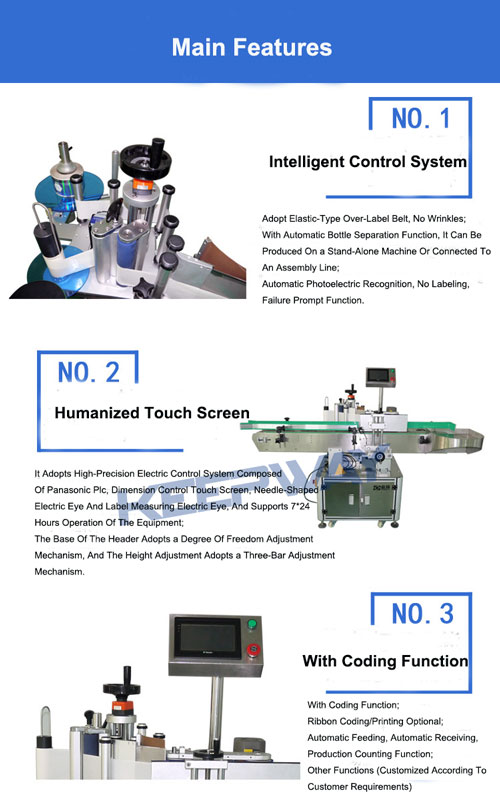

3. Excellent labeling quality, using elastic compression labeling belt, flat labeling, no wrinkles, improve packaging quality;

4.Flexible application, bottle standing labeling, with automatic bottle sorting function, can be produced by single machine, or can be connected to production line;

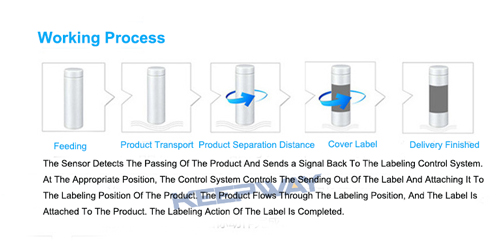

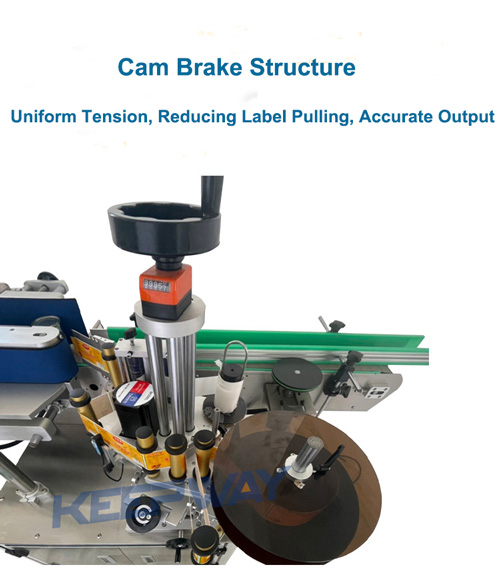

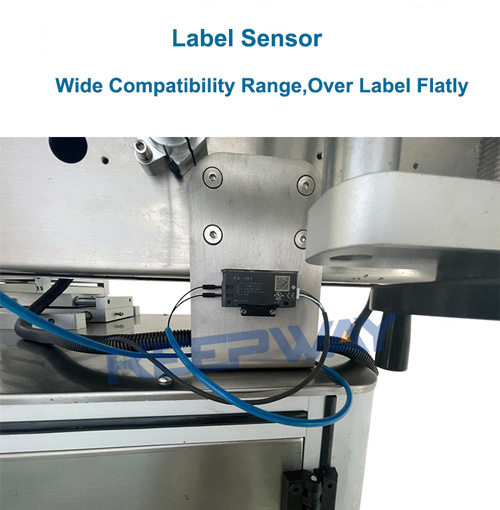

5.Intelligent control, automatic photoelectric tracking, with functions of no labeling, automatic calibration without label and automatic detection of labels to prevent missing labels and waste of labels;

6.High stability, Panasonic PLC + Panasonic touch screen + Panasonic needle electric eye + German Leuze label electric eye advanced electrical control system, supporting equipment 7 × 24 hours operation;

7.Easy adjustment, the labeling speed, conveying speed, and bottle speed can be adjusted steplessly, and can be adjusted as needed;

8.Sturdy and durable, using a three-bar adjustment mechanism, making full use of the stability of the triangle, the whole machine is solid and durable. Made of stainless steel and high-grade aluminum alloy, meeting GMP production requirements;

9.Optional function:

① Hot coding / printing function;

②Automatic loading function (considering product consideration);

③ Automatic material receiving function (considering product consideration);

④ Add labeling devices;

⑤ circumferential positioning and labeling function;

⑥ Other functions (customized according to customer requirements).

Labeling Effect:

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China